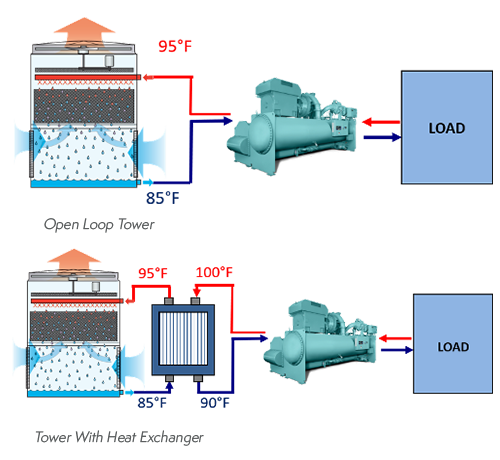

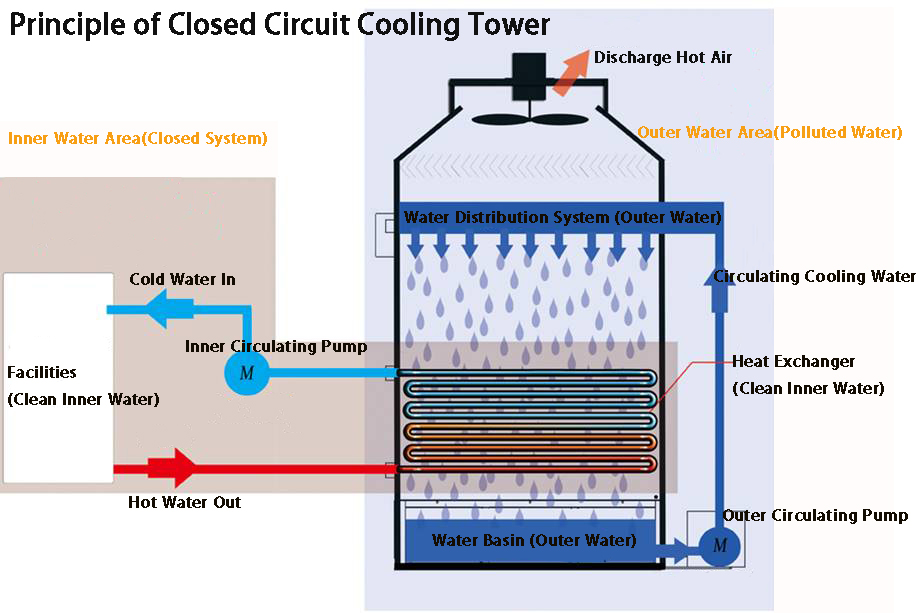

Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet bulb air temperature or in the case of closed circuit dry cooling towers rely solely on air to cool the working fluid to near.

Closed circuit cooling water system in power plant.

A cooling tower is used to cool and circulate water used in settings such as oil refineries petrochemical and other chemical plants thermal power stations and hvac systems for cooling buildings.

The rest is then sent back to the condenser in the power plant.

In the cooling towers an airflow natural or forced cools the water and the water returns to the condenser.

Cooling towers extract waste heat to the atmosphere through the cooling of a water stream to a lower temperature.

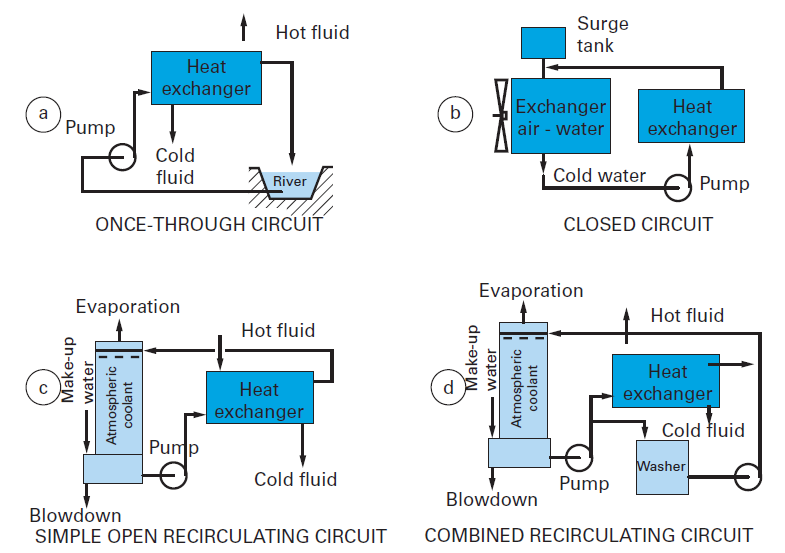

Wet recirculating or closed loop systems reuse cooling water in a second cycle rather than immediately discharging it back to the original water source.

The circulating water removes the heat from the condenser and flows to cooling towers.

As the steam in the internal circuit condenses back to water the surplus waste heat which is removed from it needs to be discharged by transfer to the air or to a body of water.

Some of the water evaporates.

Aside from emergency use closed circuit cooling systems also serve to cool down components at a power plant.

Most commonly wet recirculating systems use cooling towers to expose water to ambient air.

The second is the closed cooling system where circulating water is in a closed circuit.

Closed cooling water system in power plant.

There are two different types.

Failure of a closed system has the potential to shut down a portion if not all of the plant.

Water systems help cool bearings while other coolers chill lube air compressors and oil.

Power plants located away from large sources of water utilise.

Using a cooling system reduces the heat wear on these components and a.

A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature.

At a power plant the moving parts can generate enormous amounts of heat.

P rimary cooling at steam generating power plants and many other heavy industries is a critical aspect of operation and upsets can cost a great deal in lost efficiency and production.

The second function for water in such a power plant is to cool the system so as to condense the low pressure steam and recycle it.

This feature is not available right now.

Closed systems are also widely used in air conditioning chilled water systems to transfer the refrigerant cooling to air washers in which the air is chilled.

Other closed recirculating cooling applications include smelt spout cooling systems on kraft recovery boilers and lubricating oil and sample coolers in power plants.